CCS 8.5 inch Smart Pads™ Curved Edge Foam Pads by Lake Country

CCS Technology revolutionizes foam buffing pads!

Lake Country’s CCS 8.5 inch Smart Pads™ Foam Pads are curved edge, full contact buffing pads that work with your circular polisher to correct automotive paint more easily than ever before. The curved edge provides a lip of foam surrounding the backing plate to protect against accidental nicks. Combined with the CCS design, these pads will improve your detailing experience.

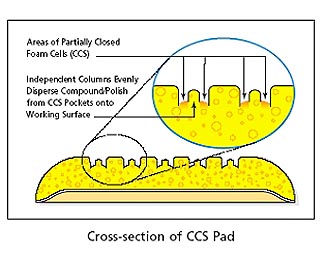

CCS stands for Collapsed Cell Structure. The face of a CCS Smart Pad™ is covered in strategically placed pockets. These pockets are locations where the foam cells have been closed. Polish does not absorb into these closed cell pockets, leaving more product on the pad's surface and on the paint. This polish-saving design gives polishes a longer working time, which results in more successful detailing. CCS Smart Pads™ work on every type of paint, from conventional clear coats to the harder, scratch-resistant clear coats used by Mercedes Benz and the Ford Motor Company. Lake Country's range of foam compositions, combined with the right chemicals, provides you with a prescription to correct almost any paint imperfection on any paint finish. What are the benefits of CCS Technology?

|

Slows rate of polish absorption – As discussed above, the pads are slow to absorb products and therefore the paint benefits from a longer working time. The same is true of liquid waxes and sealants. Improves operator control – CCS pockets gradually release polish as needed by the operator. Since these areas are not absorbing polish, they serve as little reservoirs until the excess polish is needed. Prevents pad skipping – CCS pockets reduce surface tension allowing the operator to run pad flat on a working surface. Basically, the CCS pockets break up the smooth surface of the foam to eliminate the sticking and skipping that occurs when two perfectly flat surfaces meet. Creates less heat – CCS pockets provide several points where the foam is not completely touching the paint. This reduces friction and therefore heat generated between the pad and the paint. OEM approved – OEM tests confirm CCS pads out-perform convoluted pad designs.

The longer working time afforded by the CCS pads allows you to work problem areas with greater success. The pockets reduce the amount of heat created so even though you're working the paint longer, there is no additional risk to the paint. You might remember that Autogeek used to carry pads with a splatter pocket, which was a concavity in the middle of our 7.5 and 8.5 inch pads. Ultimately, I decided that the splatter pocket reduced the amount of surface contact and it probably wasn't worth it considering you can avoid splatter by gradually increasing speed. CCS Smart Pads™ revive the idea behind the splatter pocket but the design is much better. The CCS pockets hold any extra product and gradually release it as needed. The CCS pockets function like many splatter pockets by reducing splatter and regulating the release of extra product, but you don't lose any contact surface. Each CCS Smart Pad™ features VELCRO brand hook and loop fasteners covering the entire back of each pad to secure to a hook and loop backing plate. CCS Smart Pads™ are available in 6.5 inch, 7.5 inch, and 8.5 inch. For a 6.5 inch pad, we recommend a 5 inch backing plate. For a 7.5 inch pad, we recommend a 6 inch backing plate. CCS Smart Pads™ are available in several varieties, from cutting pad to an ultrafine finishing pad.

Black Finishing Foam 8.5" - Composition is firm enough to withstand added pressure during final finishing to remove buffer swirls. It has no cut and will apply thin, even coats of waxes, sealants, and glazes.

CCS Technology is the future of foam buffing pads. These pads are easy to use, they improve operator control, they prevent product waste, they reduce heat...CCS Smart Pads™ simply do more to improve detailing results.

To clean all foam pads: Mix a scoop of McKee's 37 Polishing Pad Rejuvenator in 3-4 gallons of water before you begin detailing. When you're finished with each pad, toss it in the mixture to soak. Mild agitation with a Foam Conditioning Brush will release any polish residue. Rinse the pads and lay them flat to dry. Lay the pads foam side down. If foam pads are left to dry with the hook & loop facing down, water will settle where the hook & loop is glued to the foam and it may affect the glue. For the best results, lay pads foam side down so water drains down and out of the foam. |

Lake Country has improved upon the basic pad design with CCS technology, which actually slows the rate of product absorption and saves polish. With conventional foam pads, polish is absorbed into the foam rather quickly. This reduces the working time with the polish and may give you disappointing results. A build-up of chemicals inside the foam will also cause the pad to dry out more rapidly.

Lake Country has improved upon the basic pad design with CCS technology, which actually slows the rate of product absorption and saves polish. With conventional foam pads, polish is absorbed into the foam rather quickly. This reduces the working time with the polish and may give you disappointing results. A build-up of chemicals inside the foam will also cause the pad to dry out more rapidly. CCS foam pads provide ample surface contact to effectively work the paint. The CCS pockets are small so they don't affect the amount of foam continuously touching the paint during operation.

CCS foam pads provide ample surface contact to effectively work the paint. The CCS pockets are small so they don't affect the amount of foam continuously touching the paint during operation. Yellow Cutting Foams 8.5"- Use this pad to apply compounds or polishes to remove severe oxidation, swirls, and scratches. It is the most aggressive and should only be used on oxidized and older finishes. Always follow this pad with an orange pad and a fine polish and then a white pad to refine the paint until it is smooth.

Yellow Cutting Foams 8.5"- Use this pad to apply compounds or polishes to remove severe oxidation, swirls, and scratches. It is the most aggressive and should only be used on oxidized and older finishes. Always follow this pad with an orange pad and a fine polish and then a white pad to refine the paint until it is smooth.

White Polishing Foam 8.5"- Less dense foam formula for the application of waxes, micro-fine polishes and sealants. This pad has very light cutting power so its perfect for pre-wax cleaners.

White Polishing Foam 8.5"- Less dense foam formula for the application of waxes, micro-fine polishes and sealants. This pad has very light cutting power so its perfect for pre-wax cleaners.

Blue Finessing Foam 8.5"– Flat pad has soft composition for applying glaze,finishing polish, sealants, and liquid waxes. Flat pad provides full contact with paint surface to minimize the pressure applied by the user.

Blue Finessing Foam 8.5"– Flat pad has soft composition for applying glaze,finishing polish, sealants, and liquid waxes. Flat pad provides full contact with paint surface to minimize the pressure applied by the user.  Gold Super Soft Jewelling Foam 8.5"– Use the gold pad to apply a very fine polish or glaze as the final step of the polishing process. Jewelling is the term coined for this step because it intensifies gloss and reflectivity, like a jewel. The gold foam pad also works well for wax and sealant application.

Gold Super Soft Jewelling Foam 8.5"– Use the gold pad to apply a very fine polish or glaze as the final step of the polishing process. Jewelling is the term coined for this step because it intensifies gloss and reflectivity, like a jewel. The gold foam pad also works well for wax and sealant application. Red UltraSoft Wax/Sealant Foam 8.5"– This soft, imported foam is ideal for applying the final coat of wax or sealant. The foam works especially well when applying liquid waxes or sealants because it is firm enough to keep the majority of the product on the paint, rather than soaking it up. The red foam has no cut or cleaning ability.

Red UltraSoft Wax/Sealant Foam 8.5"– This soft, imported foam is ideal for applying the final coat of wax or sealant. The foam works especially well when applying liquid waxes or sealants because it is firm enough to keep the majority of the product on the paint, rather than soaking it up. The red foam has no cut or cleaning ability.