Description

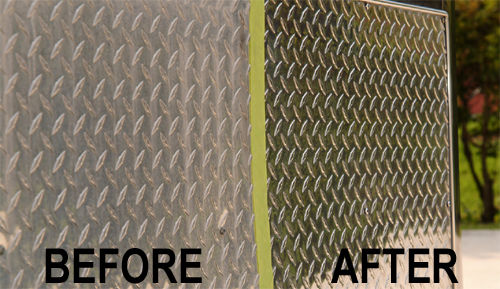

Erase dullness, spots, and discoloration from aluminum to uncover a smooth, silky finish.

Wolfgang MetallWerk™ Aluminum Compound is a strong aluminum prepolish that powers through oxidation and discoloration on aluminum to create a smooth, uniform finish. This is step one of a three part restoration process that results in a high impact, incredibly reflective shine on aluminum trailers, wheels, trim, boats, aircraft, and more.

Aluminum can be a challenge to polish because you are not dealing with a coating that can easily be leveled. Instead you are removing imperfections from the aluminum itself. Aluminum and other bare metals require an intense abrasive polish to remove rust and stains. Complete restoration is a multi-step process and it all begins with Wolfgang MetallWerk™ Aluminum Compound. Wolfgang MetallWerk™ Aluminum Compound is step one for severely oxidized or never before polished aluminum surfaces. This is an ammonia-based, abrasive polish designed to remove rust, water spots, and stains from weathered aluminum surfaces. This is the same aluminum polishing technology used by major aircraft manufacturers. MetallWerk™ Aluminum Compound can also be used on chrome, copper, stainless steel, and magnesium. The diminishing abrasives quickly level surface rust and polish away spots and stains. You’re left with a clean, satin finish. To get the bright, reflective finish of new aluminum, you have to use step two, Wolfgang MetallWerk™ Fine Aluminum Polish. |

|

This is a strong polish! After using it, you may see some light swirls. Step two will eliminate these swirls and create a brilliant shine.

Wolfgang MetallWerk™ Aluminum Compound should be applied with a dual action or rotary polisher. A dual action machine, like the Porter Cable 7424XP, may not have the bite to remove severe stains but it will greatly improve them. If you have a severe case of oxidation on your hands, we suggest using a rotary polisher. If using a rotary machine, the same rules apply as if you were polishing paint. Keep the polisher moving at all times. It can burn the metal. If this happens, allow the area to cool. Then go back over it with the polisher to remove the burn.

Warning! Wolfgang MetallWerk™ Aluminum Compound should not be used on anodized, plated, painted, or coated metals.

|

|

|

|

|

|

Polishing Trailers, Diamond Plate & Aircraft:

- Put a 4 Ply Twisted Wool Compounding Pad onto your polisher. Wool is the best choice for diamond plate because of the uneven surface.

- Wipe a thin layer of Wolfgang MetallWerk™ Aluminum Compound onto the desired surface.

- Polish between 1200- 1500 RPM (or 5-6 OPM on a dual action polisher). Polish until the aluminum appears clean and glossy.

Note: It may take several passes to completely remove severe oxidation. See the wool pad cleaning instructions below.

* On aluminum, brass and copper, a black residue will appear as you polish.

* On chrome and stainless steel, no residue will appear. Polish until stains disappear. - Wipe the surface clean. If the surface is clean and smooth with a satin gloss, continue to Wolfgang MetallWerk™ Fine Aluminum Polish. If you can see stains or oxidation, repeat this process until a uniform shine is achieved. Have plenty of old towels on hand for removing polish residue.

Note: Restoring aluminum is a long, messy process. Depending on the severity of oxidation, you may produce a lot of black residue as you polish and go through more than one pad. Keep at least one additional pad on hand in case the one you’re using becomes too caked with residue. Fluffing the pad will help prolong the use of each pad before you need to switch to a clean one. Toss each used pad into a bucket of water and Wolfgang Polishing Pad Rejuvenator to immediately start soaking.

Polishing Wheels & Trim: Tape off the paint or plastic surrounding the area to be polished. For application to small areas, you can use Mothers PowerBall or the Flitz Polishing Ball on your electric drill.

|  |

|

How To Clean Wool Pads

As you’re working, check the wool pad periodically to make sure it has not become caked with polish. This also makes the pad less effective. Take a moment to fluff the pad by holding the Duo Spur Pad Cleaning Tool to the wool as the pad spins. The Duo Spur is a safer way to fluff the pad than steel because a steel brush can remove many wool strands. The Duo Spur has plastic teeth to push excess polish out of the wool and to restore the texture.

|  |  |